Polyphenylthioethers

(Armoatic Polythiols)

Properties

The most widely used polyphenylthioether is poly(para-phenylene sulfide) (PPS), also called polyphenylene sulfide (PPS). It is a semicrystalline engineering thermoplastic with a relativly high melting point of about 560 K. Because of its high melting point and its poor solubility, special processing methods have to be used to manufacture products from this resin. For example, PPS can be compression molded at temperatures between 550 and 650 K, at which PPS softens and undergoes crosslinking reactions to yield a totally insoluble plastic.

PPS has outstanding heat and chemical resistance, good dimensional stability as well as high tensile and flexural strength due to the aromatic ring structure of the polymer backbone (see below). Although the mechanical properties drop somewhat with increasing temperature, they level off at approximately 395 K, and moderately high mechanical properties can be expected up to 530 K (256°C).

PPS is typically reinforced with glass fibers or mineral fillers. These grades have improved mechanical strength, are noticeably stiffer (higher modulus), and exhibit better strength retention at elevated temperature (higher heat deflection temperature, HDT). They also exhibit improved flame retardance and exceptional electrical and electronic properties, including outstanding dielectric strength which is exceptionally stable over a wide range of temperatures and frequencies.

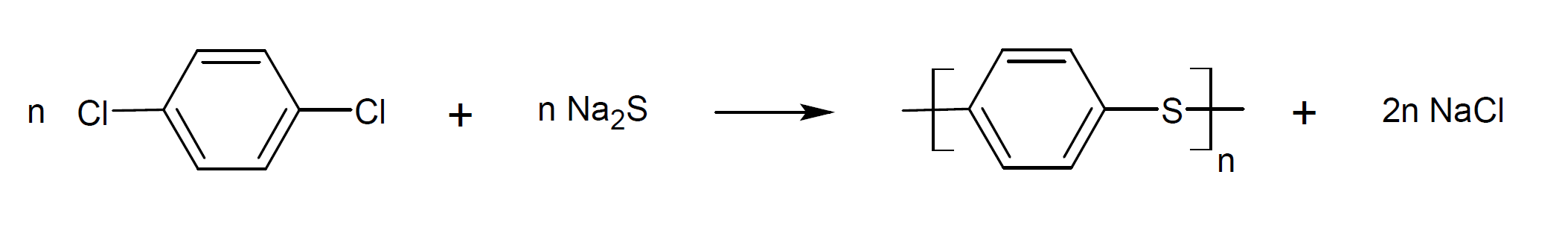

Commercial polyphenylene sulfide is produced by the condensation reaction between p-dichlorobenzene and sodium sulfide in a polar solvent. The reaction is shown below:

Other polyphenylthioether (polymercaptan) that have been synthesized are poly(methylene-1,4-phenylene-methylene disulfide) and poly(methylene-thiomethylene-1,4-phenylene-methylene. These polymers, however, have found little or no commercial use.

COMMERCIAL POLYPHENYLTHIOETHERS

Commercial grades of PPS are available under the trade names Ryton® and Fortron®. Most grades are glass fiber or mineral filler reinforced to improve their mechanical and electrical properties.

APPLICATIONS

Poly(p-phenylene sulfide) is the most widely used polythioether. This semi-crystalline engineering thermoplastic has many attractive mechanical and electrical properties. For example, it offers high thermal stability and outstanding dielectric strength, which is exceptionally stable over a wide range of temperatures and frequencies. Because of these properties, it is extensively used for electrical and electronic parts such as plugs, connectors, relays, switches, and encapsulation of electronic parts. Other applications include mechanical parts in automobiles and precision engineering like air intake systems, pump parts, gaskets, valves, bushings, and bearings, particularly for service in corrosive environments.